Position: Home>News Center>News>Daily maintenance method of "wide flow channel plate heat exchanger"

News

Daily maintenance method of "wide flow channel plate heat exchanger"

Source

:http://www.puruipule.cn

Time:2020-09-15 16:00:41

Clicks:547

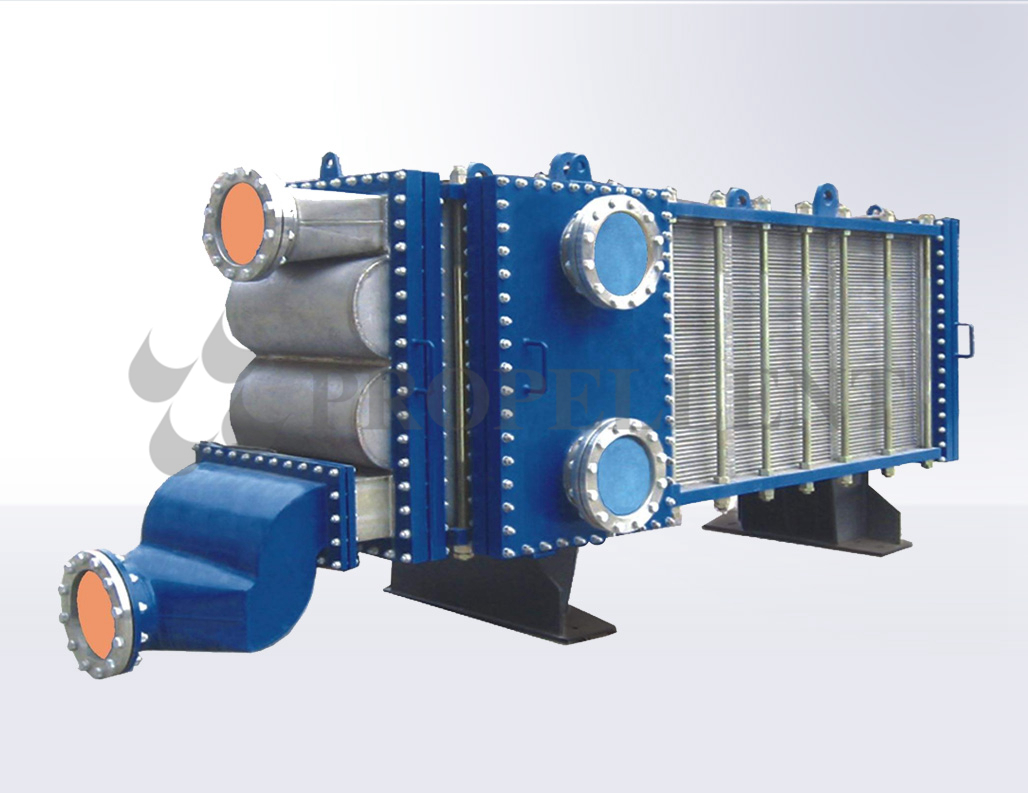

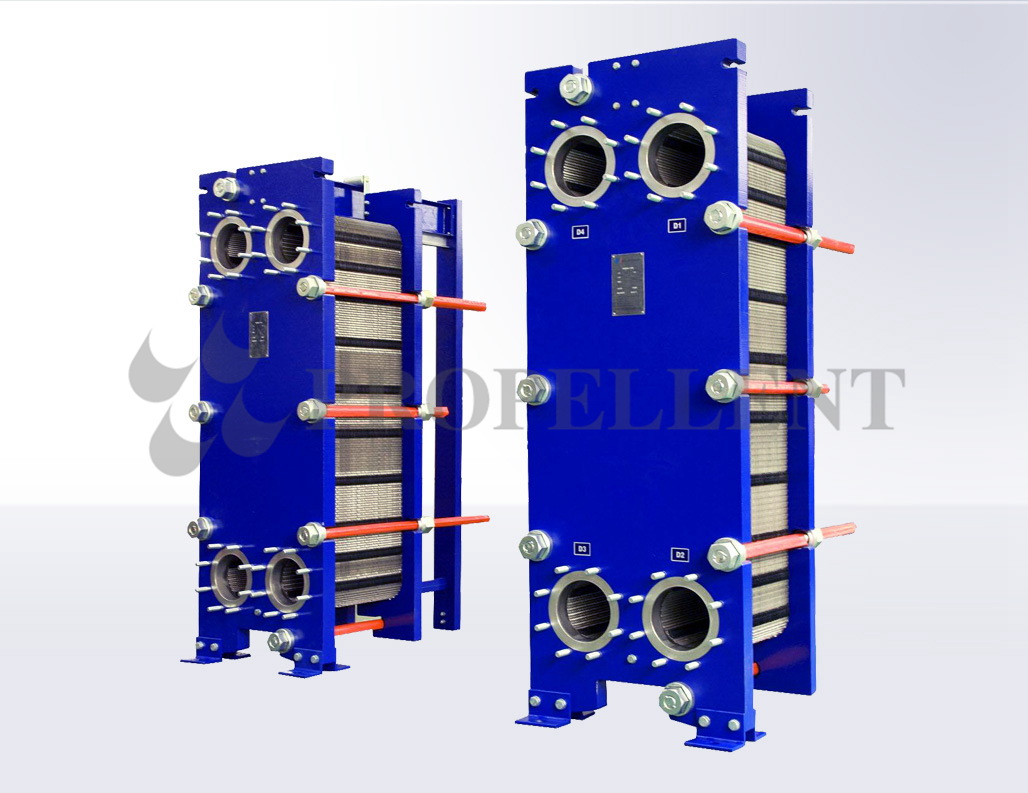

The wide flow channel plate heat exchanger is a product specially developed for the heat exchange conditions of various solids, crystals, fibers, slurry substances and high viscosity media. There are no metal contact points between the plates. The S-shaped fluid channel form ensures a wide The gap channel is smooth, and the fluid flows smoothly without clogging.

The following editor of Propellent explains the daily maintenance methods of wide-channel plate heat exchangers:

1. Keep the equipment clean and well painted. The threaded part of the clamping bolt should be coated with anti-rust oil and protective cover to prevent rust and sticking dust.

2. It needs to be disassembled, inspected and cleaned regularly according to actual conditions.

3. When there are large particles in the material, they will gather at the outer end of the diversion opening where the material enters the plate, reducing the flow rate of the material into the heat exchanger and forming a larger resistance. When encountering such working conditions, a self-cleaning intelligent heat exchange system can be used to easily solve the problem of material accumulation and reduce or avoid disassembly and cleaning.

4. Check whether the pressure gauge and temperature gauge are sensitive, whether the data is accurate, and there is no leakage of valves and flanges.

5. Check whether the plate is damaged, whether the gasket is aging, and if necessary, replace it in time.

6. When reassembling the heat exchanger, the plates and gaskets should be kept clean, the plates should be placed neatly and flatly, and the plates should be assembled according to the product assembly drawing.

7. When the wide-channel plate heat exchanger is stopped in winter, the medium in the heat exchange equipment should be vented to avoid freezing the equipment.

The following editor of Propellent explains the daily maintenance methods of wide-channel plate heat exchangers:

1. Keep the equipment clean and well painted. The threaded part of the clamping bolt should be coated with anti-rust oil and protective cover to prevent rust and sticking dust.

2. It needs to be disassembled, inspected and cleaned regularly according to actual conditions.

3. When there are large particles in the material, they will gather at the outer end of the diversion opening where the material enters the plate, reducing the flow rate of the material into the heat exchanger and forming a larger resistance. When encountering such working conditions, a self-cleaning intelligent heat exchange system can be used to easily solve the problem of material accumulation and reduce or avoid disassembly and cleaning.

4. Check whether the pressure gauge and temperature gauge are sensitive, whether the data is accurate, and there is no leakage of valves and flanges.

5. Check whether the plate is damaged, whether the gasket is aging, and if necessary, replace it in time.

6. When reassembling the heat exchanger, the plates and gaskets should be kept clean, the plates should be placed neatly and flatly, and the plates should be assembled according to the product assembly drawing.

7. When the wide-channel plate heat exchanger is stopped in winter, the medium in the heat exchange equipment should be vented to avoid freezing the equipment.

Keywords:plate heat exchanger