The plate of all-welded plate heat exchanger is made from a special stainless steel with a special pressing mold. It is not easy to scale because of smooth surface. Its unique corrugated design make fluid under low velocity also generates turbulence with high heat transfer efficiency. The whole plate is welded by argon arc welding with body materials. It does not use any nonmetal sealing material, which have higher heat resistance, compression performance.

Application:

Apply to the temperature from 195 ℃ to 538 ℃, Almost all of the heat transfer process with pressure from vacuum to 8.2 MPa.

Product Composition:

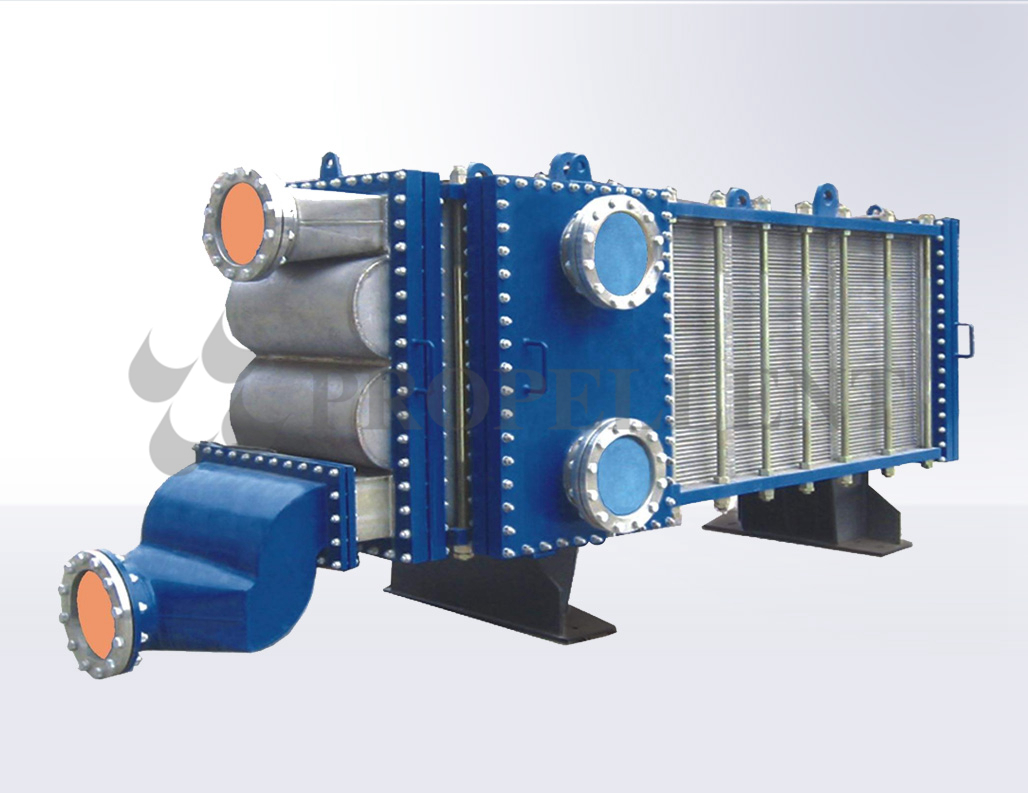

All-welded wide channel plate heat exchanger is a kind of plate heat exchanger made by welding, the heat exchanger consists of plate bundle, guide tube, buffer box, clamping plate, clamping bolt, flange cover and support etc. The plate bundle is core of heat transfer, the thermal performance of heat exchanger is decided by plate as heat transfer elements. The loading capacity and operation safety are decided by buffer box, clamping plate and clamping bolt.

Operating Principle:

All-welded wide channel plate heat exchanger is a kind of recuperative heat exchanger. The structure of the heat exchanger uses the width channel combination mode, wide flow channel materials and narrow groove cooling medium. It can design different width of channels according to the medium parameters. Generally, the fluid channel on the side of wide runner is named plate side, and the fluid channel on the side of narrow runner is named tube side. The fluid with high temperature transfers heat to another fluid with lower temperature when tube side and plate side flow different fluid with different temperature, the fluid with high temperature is cooled and the fluid with low temperature is heated to achieve heat exchange.

Our selection methods:

We will look for insights into your technology and have an effective communication with your engineer to settle down a perfect solution, this solution will be more accurate and apply to users’ working condition, it will be in favor of reducing purchase cost and energy consumption (water, electricity and gas).

Our technical engineer can provide professional selection solution and drawings for our clients by calculation software according to users’ working condition, we will select fitting solution to give you stable and efficient service.

We will be more responsible for your working conditions to reduce your equipment procurement costs and energy consumption of your process operation(water, electricity, gas).

- Last: Semi-welded pla

- Next: Brazing plate h