Industry news

Application of plate heat exchanger in paper industry

Source

:http://www.puruipule.cn

Time:2020-03-25 11:13:13

Clicks:519

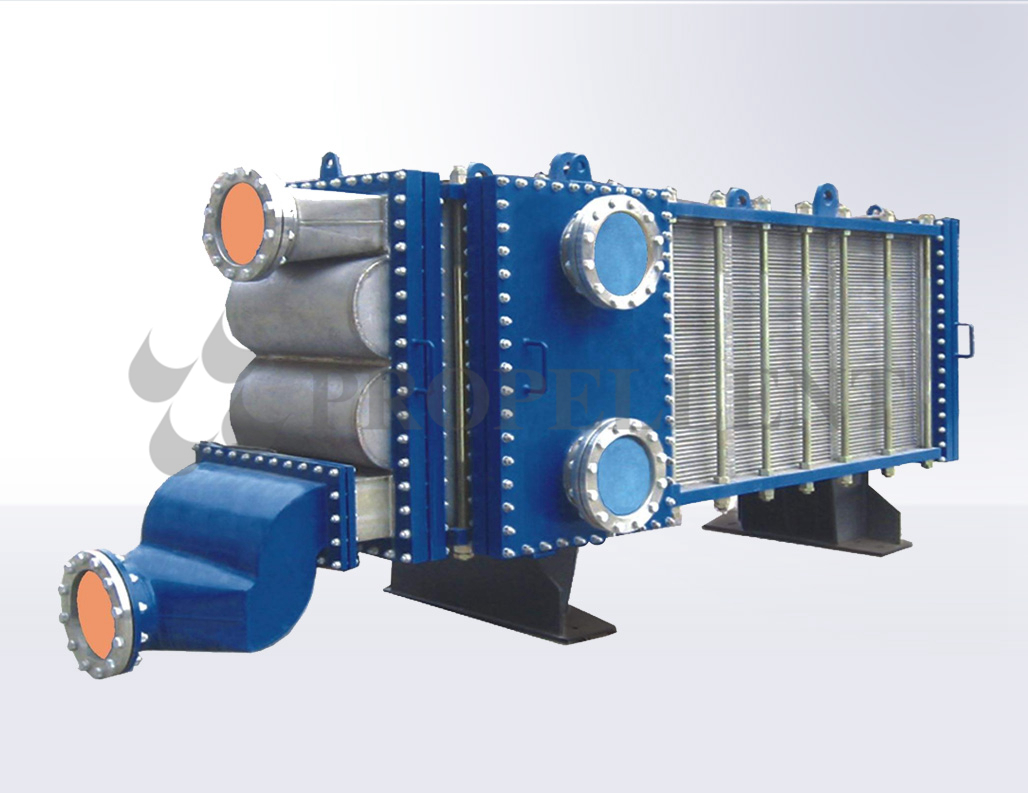

Pulp cooking refers to a pulping process in which papermaking raw materials and cooking liquor are put into a cooker and then heated by steam to remove the non-cellulose portion of the fibrous material. The boiling black liquor of papermaking has high calorific value and good flammability, and it is an important self-generated energy in the papermaking industry. Prepler's heat exchanger products can be used as a series of key energy-saving equipment in the black liquor concentration process, which is an important measure to improve the energy utilization of paper mills.

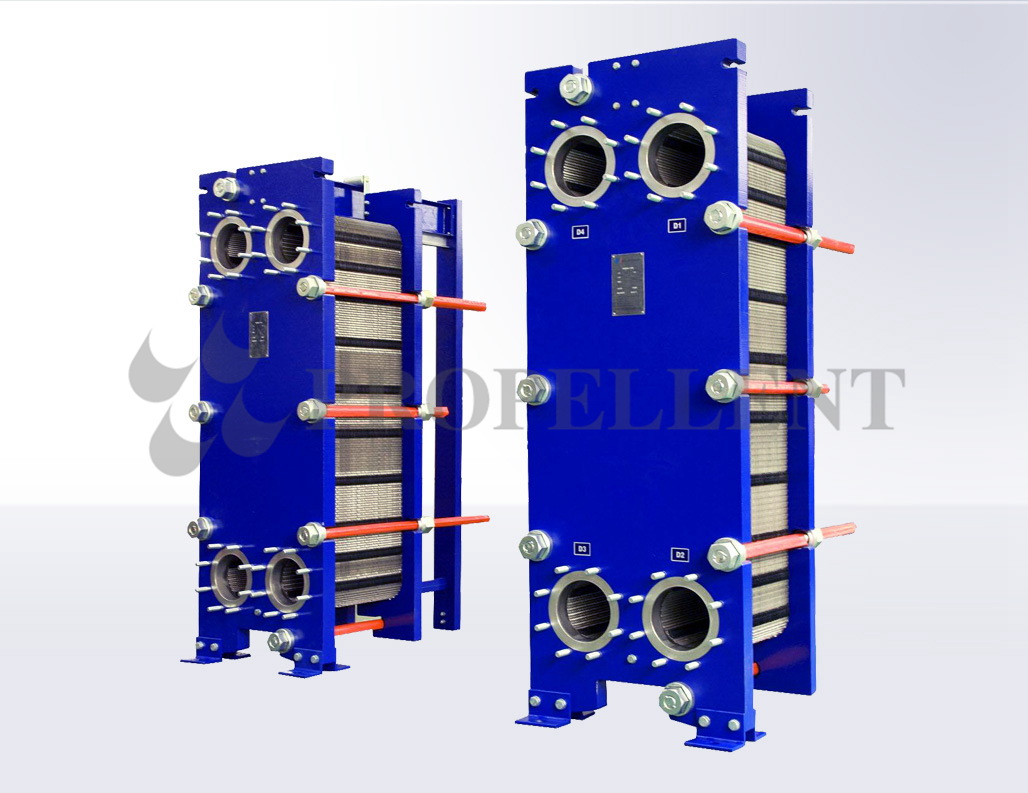

Heat exchangers are an important part of pulp and paper mills. With the help of heat exchangers, paper mills benefit greatly from energy savings.

There are many processes in paper mills that can utilize heat exchangers, especially plate heat exchangers, which take up little space, have high heat recovery efficiency, are easy to maintain, and have low cost.

Essentially, the paper processing line, starting with wood pulp processing and refining, and then bleaching and cleaning before the paper is formed, is done with the help of heat exchangers. Specifically, plate heat exchangers are used to heat the liquid used to make pulp from wood, a process that involves pulling chemical compounds away from the wood structure, leaving behind a thick substance that can form paper after more processing. Secondary processing involves stirring or drying the pulp, a process that is also heated by a plate heat exchanger. After reaching the desired color, the pulp is turned into paper by a paper machine, which weaves the pulp into a tissue web that forms a sheet of paper. During this time all moisture is removed and it is dried using some type of blower.

Part of the paper machine also uses a heat exchanger called a waste heat recovery system, which is one of the ways the heat exchanger can save energy, resources and money for the paper mill. Waste heat recovery is a waste heat recovery system. It is able to absorb the heat and moisture in the room for reuse without putting more pressure on the energy that normally provides air and water for paper processing.

Heat exchangers are an important part of pulp and paper mills. With the help of heat exchangers, paper mills benefit greatly from energy savings.

There are many processes in paper mills that can utilize heat exchangers, especially plate heat exchangers, which take up little space, have high heat recovery efficiency, are easy to maintain, and have low cost.

Essentially, the paper processing line, starting with wood pulp processing and refining, and then bleaching and cleaning before the paper is formed, is done with the help of heat exchangers. Specifically, plate heat exchangers are used to heat the liquid used to make pulp from wood, a process that involves pulling chemical compounds away from the wood structure, leaving behind a thick substance that can form paper after more processing. Secondary processing involves stirring or drying the pulp, a process that is also heated by a plate heat exchanger. After reaching the desired color, the pulp is turned into paper by a paper machine, which weaves the pulp into a tissue web that forms a sheet of paper. During this time all moisture is removed and it is dried using some type of blower.

Part of the paper machine also uses a heat exchanger called a waste heat recovery system, which is one of the ways the heat exchanger can save energy, resources and money for the paper mill. Waste heat recovery is a waste heat recovery system. It is able to absorb the heat and moisture in the room for reuse without putting more pressure on the energy that normally provides air and water for paper processing.

Keywords:plate heat exchanger