Industry news

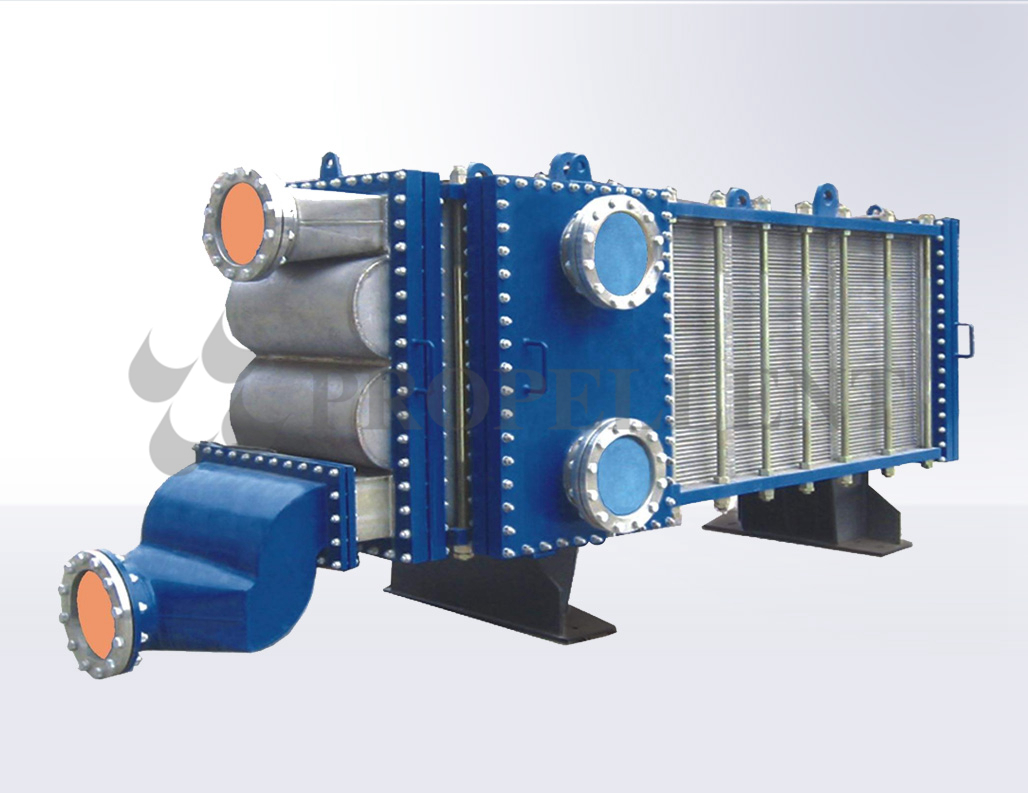

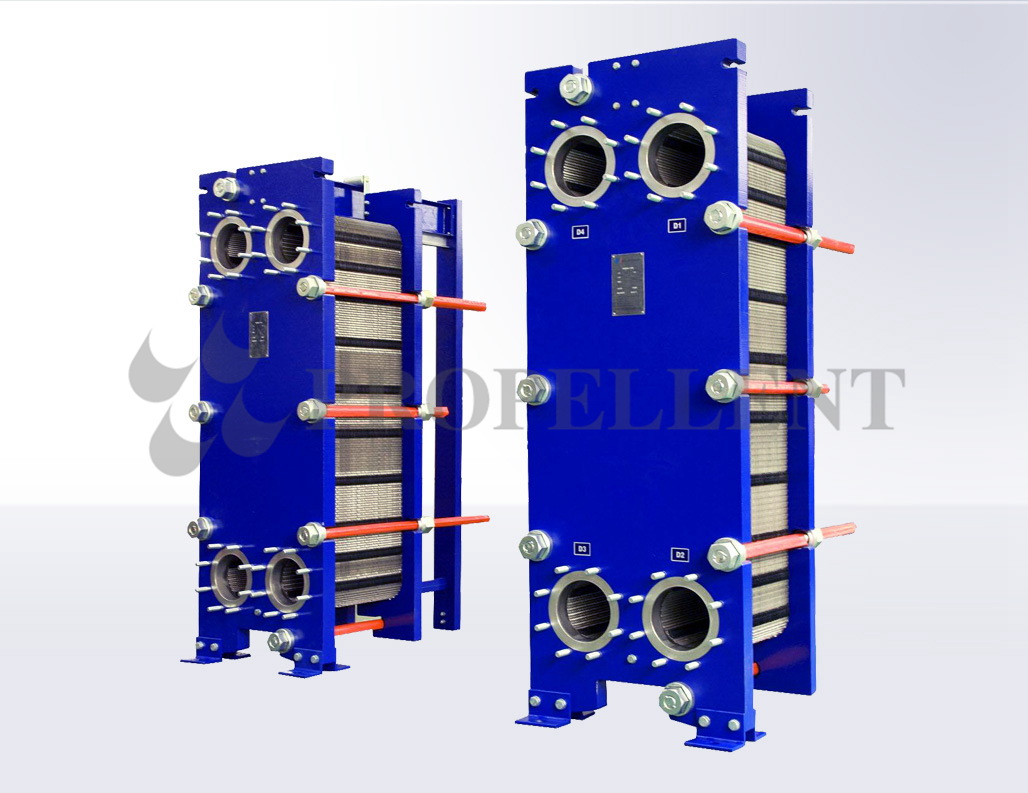

Features and advantages of marine plate heat exchanger:

Source

:http://www.puruipule.cn

Time:2020-03-23 15:29:58

Clicks:322

1. Ship equipment has compact structure and low quality.

Plate heat exchangers for marine turbines are usually much smaller than conventional heat exchangers. In order to meet the requirements of marine equipment, unnecessary parts of the heat exchanger should be removed or reduced according to the actual stress and strain distribution, and the weak parts are locally thickened. Reduce the influence of welding deformation on the strength, weld the inner plate and the panel together to eliminate the residual stress. Use equipment in limited space as much as possible to complete the heat transfer work to ensure the normal use of the ship.

2. Ship equipment has problems such as impact force, large-angle vibration, and vibration.

A multi-point fixing method is used at the bottom of the plate heat exchanger, that is, all fixed parts can use fixed connections. Some important special components also use "rib" structure, which greatly increases the stability of the equipment. Only by improving the installation stability can the heat exchange efficiency and the effect of the heat exchanger be ensured. Once problems such as vibration occur, it will affect the heat transfer effect.

3. The cooling medium should consider the problem of high seawater and chloride ion concentration

Many turbines are in direct contact with seawater and have a very large effect on the heat transfer medium during use. Therefore, the plates used in turbine heat exchangers are usually made of materials with high corrosion resistance, such as titanium, which have a mass much smaller than stainless steel. In order to ensure the quality of the titanium plate, in addition to the regular inspection, a 100% color penetration test is also performed on the plate to further eliminate the error when the plate is sampled.

4. Heat transfer medium problem

Because the specific heat capacity difference between water and oil is relatively large, the temperature difference is large during the heat transfer process, and the heat transfer coefficient is also large. In order to make the product reliable and economical, it is necessary to ensure the oil and water heat transfer performance under the working conditions of the ship to ensure that the equipment has a certain amount of heat exchange margin. Only when the heat medium can conduct heat effectively can the heat transfer effect be achieved.

5. Low price and strong operability

Propellent plate heat exchangers are inexpensive and the production process is very mature. During production or maintenance, we will minimize costs and increase efficiency. Usually, it can be cleaned by loosening the screws in the mounting structure, reassembled and reused. Cost-effective, can be stored in emergency equipment.

Plate heat exchangers for marine turbines are usually much smaller than conventional heat exchangers. In order to meet the requirements of marine equipment, unnecessary parts of the heat exchanger should be removed or reduced according to the actual stress and strain distribution, and the weak parts are locally thickened. Reduce the influence of welding deformation on the strength, weld the inner plate and the panel together to eliminate the residual stress. Use equipment in limited space as much as possible to complete the heat transfer work to ensure the normal use of the ship.

2. Ship equipment has problems such as impact force, large-angle vibration, and vibration.

A multi-point fixing method is used at the bottom of the plate heat exchanger, that is, all fixed parts can use fixed connections. Some important special components also use "rib" structure, which greatly increases the stability of the equipment. Only by improving the installation stability can the heat exchange efficiency and the effect of the heat exchanger be ensured. Once problems such as vibration occur, it will affect the heat transfer effect.

3. The cooling medium should consider the problem of high seawater and chloride ion concentration

Many turbines are in direct contact with seawater and have a very large effect on the heat transfer medium during use. Therefore, the plates used in turbine heat exchangers are usually made of materials with high corrosion resistance, such as titanium, which have a mass much smaller than stainless steel. In order to ensure the quality of the titanium plate, in addition to the regular inspection, a 100% color penetration test is also performed on the plate to further eliminate the error when the plate is sampled.

4. Heat transfer medium problem

Because the specific heat capacity difference between water and oil is relatively large, the temperature difference is large during the heat transfer process, and the heat transfer coefficient is also large. In order to make the product reliable and economical, it is necessary to ensure the oil and water heat transfer performance under the working conditions of the ship to ensure that the equipment has a certain amount of heat exchange margin. Only when the heat medium can conduct heat effectively can the heat transfer effect be achieved.

5. Low price and strong operability

Propellent plate heat exchangers are inexpensive and the production process is very mature. During production or maintenance, we will minimize costs and increase efficiency. Usually, it can be cleaned by loosening the screws in the mounting structure, reassembled and reused. Cost-effective, can be stored in emergency equipment.

Keywords:plate heat exchanger