News

What are the precautions for finned tube heat exchangers

Source

:http://www.puruipule.cn

Time:2020-03-13 13:59:09

Clicks:365

Copper tube aluminum finned tube heat exchangers are widely used in air heat exchange systems. Let's share the copper tubes with you today.

Relevant matters needing attention when installing aluminum fin radiator!

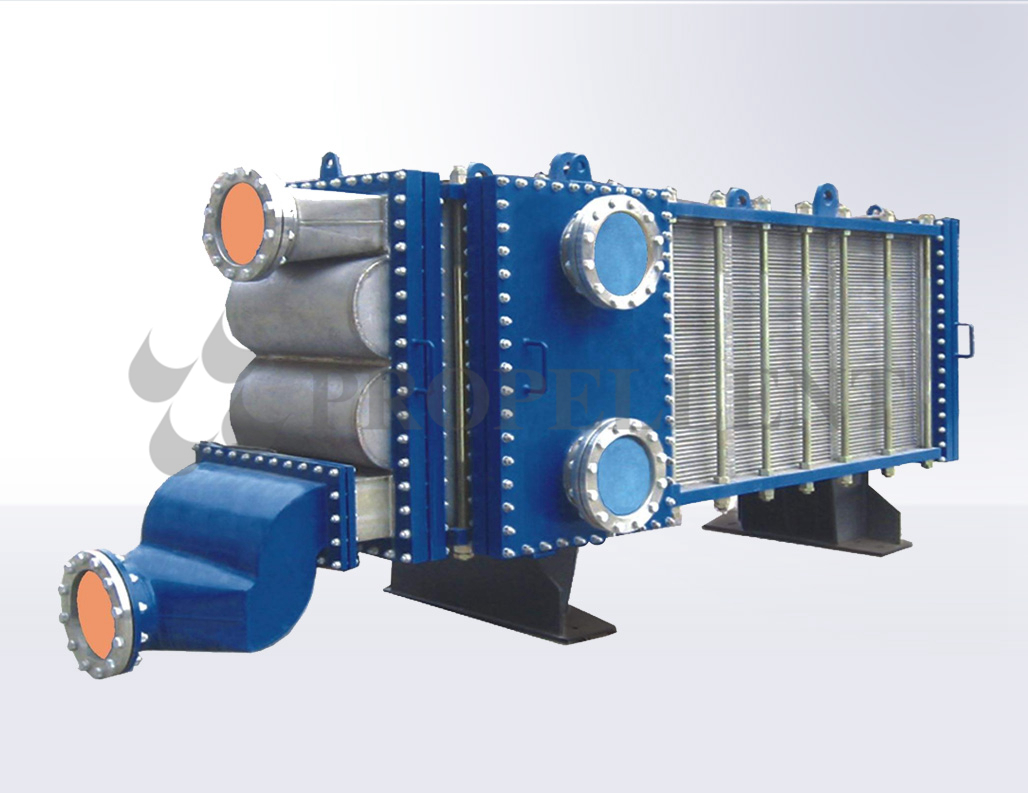

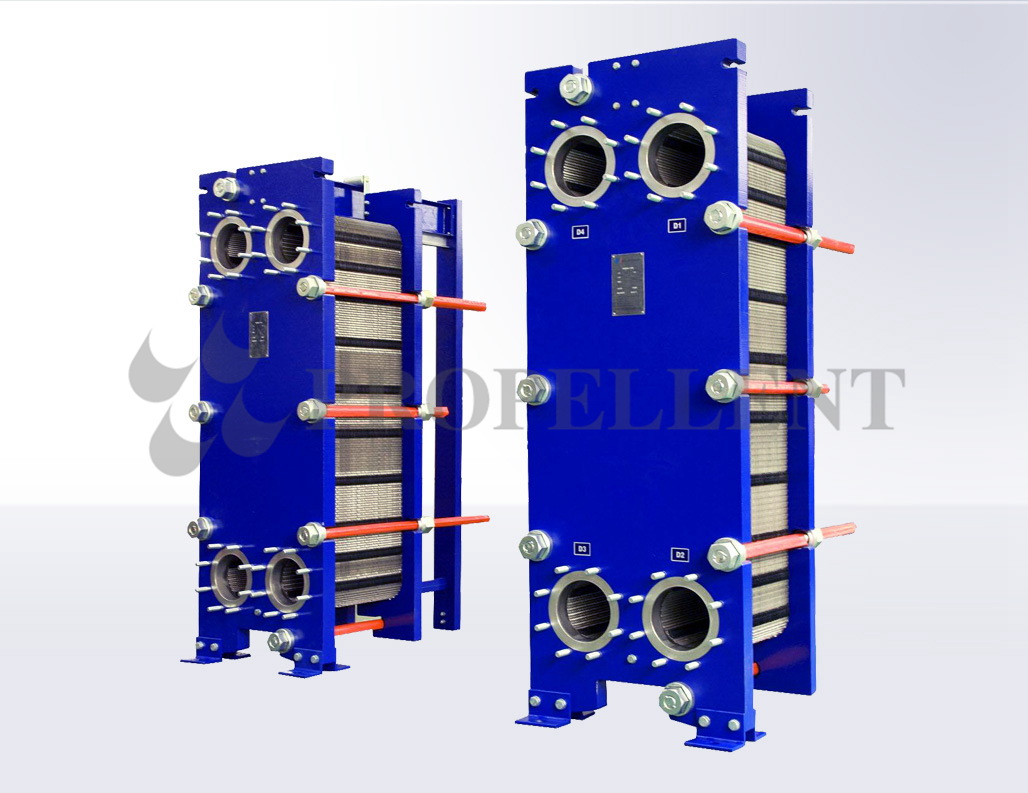

Copper tube aluminum fin Radiator is a cooling unit composed of copper tube wound aluminum fin tube and perforated plate outer frame, mainly used for large

The heat exchange system for centralized air supply heating and drying in medium-sized spaces, due to its compact structure, good air tightness, good thermal conductivity and pressure

It is easy to install and is currently widely used heating equipment for air heat exchange systems.

Its installation is simple, mainly divided into two aspects: whether the heat medium is steam or hot water. -Normally there will be a stress test before leaving the factory,

Pass the test before leaving the factory. The steam type copper tube aluminum fin radiator is installed in the way up and down to drain the tube.

Air and sufficient heat exchange, after use, stop the supply of steam before closing the gate valve. The hot water type is installed in the opposite way to dissipate heat

The structure of the device is also slightly different, but after use, the hot water supply is stopped before the gate valve is closed. Real specific installation plan

Manufacturers can be required to issue technical drawings, which will be much more convenient and safer.

In addition to the above, there are five points to note in the installation:

1.Check the integrity of the heater before installation;

2.Circulating hot water pump should be installed on the return water line;

3.The motor wiring should make the fan impeller rotate in the direction indicated by the rotating label;

4. After the heating season, the interior of the radiator should be filled with water;

5. It must be kept clean, and compressed air can be used to blow away dust from the fins and other parts of the heat exchanger;

Relevant matters needing attention when installing aluminum fin radiator!

Copper tube aluminum fin Radiator is a cooling unit composed of copper tube wound aluminum fin tube and perforated plate outer frame, mainly used for large

The heat exchange system for centralized air supply heating and drying in medium-sized spaces, due to its compact structure, good air tightness, good thermal conductivity and pressure

It is easy to install and is currently widely used heating equipment for air heat exchange systems.

Its installation is simple, mainly divided into two aspects: whether the heat medium is steam or hot water. -Normally there will be a stress test before leaving the factory,

Pass the test before leaving the factory. The steam type copper tube aluminum fin radiator is installed in the way up and down to drain the tube.

Air and sufficient heat exchange, after use, stop the supply of steam before closing the gate valve. The hot water type is installed in the opposite way to dissipate heat

The structure of the device is also slightly different, but after use, the hot water supply is stopped before the gate valve is closed. Real specific installation plan

Manufacturers can be required to issue technical drawings, which will be much more convenient and safer.

In addition to the above, there are five points to note in the installation:

1.Check the integrity of the heater before installation;

2.Circulating hot water pump should be installed on the return water line;

3.The motor wiring should make the fan impeller rotate in the direction indicated by the rotating label;

4. After the heating season, the interior of the radiator should be filled with water;

5. It must be kept clean, and compressed air can be used to blow away dust from the fins and other parts of the heat exchanger;

Keywords:plate heat exchanger