Position: Home>News Center>Industry news>Several factors affecting the sealing rubber pad of plate heat exchanger

Industry news

Several factors affecting the sealing rubber pad of plate heat exchanger

Source

:http://www.puruipule.cn

Time:2020-02-28 15:53:51

Clicks:384

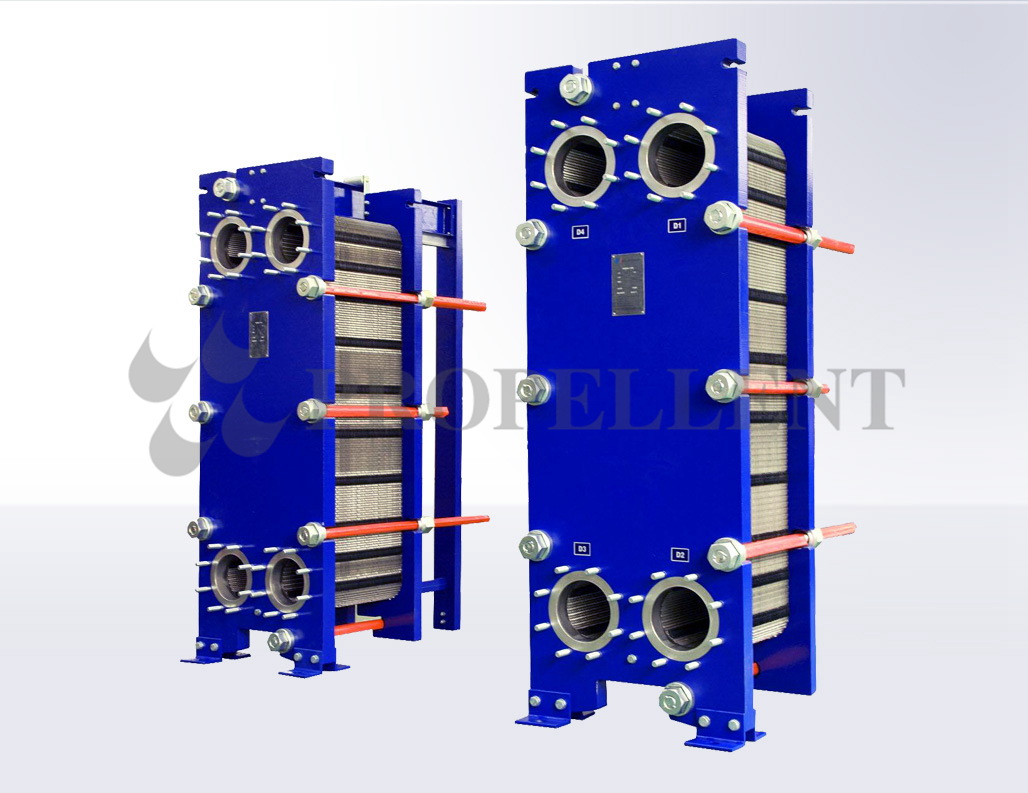

As a heat exchange device, the plate heat exchanger has a wide range of applications, which can be used for heating, cooling, and waste heat recovery. The main components of a plate heat exchanger include plates and sealing gaskets. During use, some factors may affect the sealing rubber pads, making the plate heat exchanger seal ineffective. Let's introduce it in detail below:

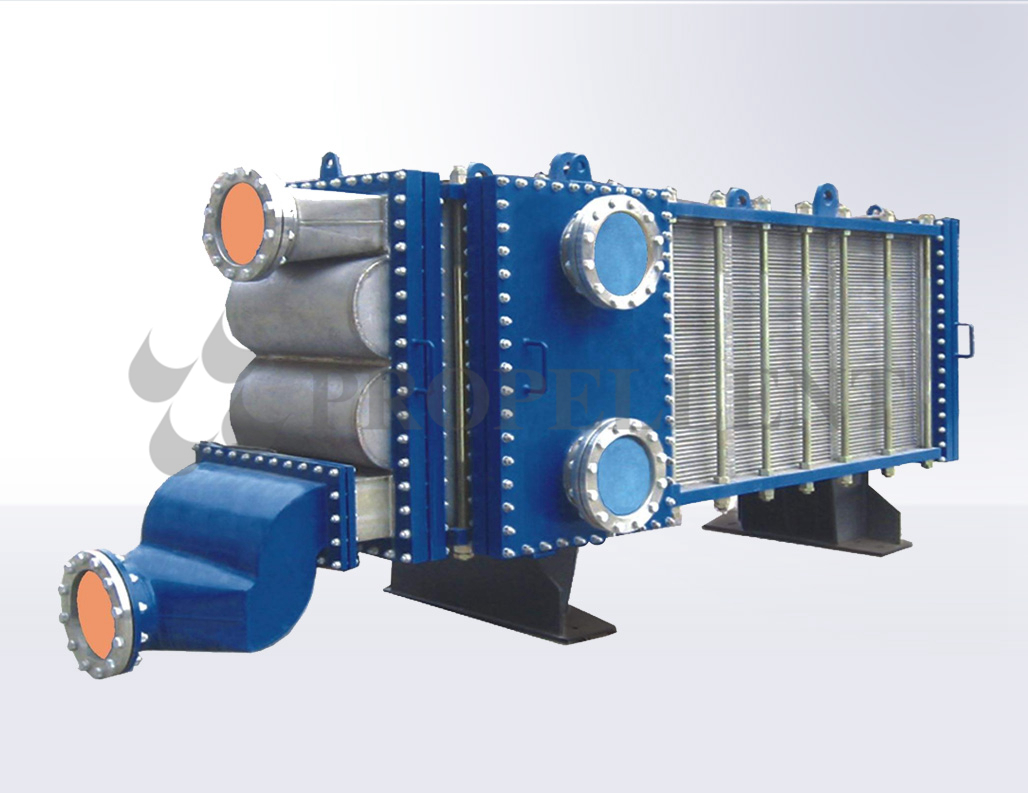

First, the influence of pressure makes the plate heat exchanger leak. When an abnormal shock load occurs in the system, the seal cushion may shift due to the large peak value of the instantaneous shock pressure, and it is not easy to detect at the same time. Generally speaking, this type of device uses stainless steel template as the material, which has poor impact resistance. Compared with shell and tube plate heat exchanger, the sealing rigidity is better.

Second, time affects the reliability of the sealing material. If the device is left unused for a long time, the sealing material will also age, which affects the tightness of the device. Therefore, it is required to regularly overhaul the device and replace it with a new gasket to ensure the normal use of the device. In addition, we can also use a protective cover or insulation layer on the outside of the plate heat exchanger to reduce the impact of the surrounding environment on the gasket.

Third, the temperature affects the seal failure of the plate heat exchanger. When the device temperature changes rapidly, it will affect the linear expansion system of the gasket, the amount of elastic deformation, and the preload of the seal cannot be matched. At this time, the seal pre-tightening force is reduced, which makes the pressure bearing of the device lower. So try to avoid rapid temperature changes to avoid damage to the gasket.

In summary, several factors that affect the use of sealing rubber pads include pressure, temperature, and aging. In use, pay attention to inspection at any time in order to solve problems in a timely manner and prevent more serious failures. At the same time, we must also pay attention to the quality factors of the plate heat exchanger. Using products from regular manufacturers, the quality is more guaranteed.

First, the influence of pressure makes the plate heat exchanger leak. When an abnormal shock load occurs in the system, the seal cushion may shift due to the large peak value of the instantaneous shock pressure, and it is not easy to detect at the same time. Generally speaking, this type of device uses stainless steel template as the material, which has poor impact resistance. Compared with shell and tube plate heat exchanger, the sealing rigidity is better.

Second, time affects the reliability of the sealing material. If the device is left unused for a long time, the sealing material will also age, which affects the tightness of the device. Therefore, it is required to regularly overhaul the device and replace it with a new gasket to ensure the normal use of the device. In addition, we can also use a protective cover or insulation layer on the outside of the plate heat exchanger to reduce the impact of the surrounding environment on the gasket.

Third, the temperature affects the seal failure of the plate heat exchanger. When the device temperature changes rapidly, it will affect the linear expansion system of the gasket, the amount of elastic deformation, and the preload of the seal cannot be matched. At this time, the seal pre-tightening force is reduced, which makes the pressure bearing of the device lower. So try to avoid rapid temperature changes to avoid damage to the gasket.

In summary, several factors that affect the use of sealing rubber pads include pressure, temperature, and aging. In use, pay attention to inspection at any time in order to solve problems in a timely manner and prevent more serious failures. At the same time, we must also pay attention to the quality factors of the plate heat exchanger. Using products from regular manufacturers, the quality is more guaranteed.

Keywords:plate heat exchanger