Industry news

Matters needing attention in the use of plate heat exchanger.

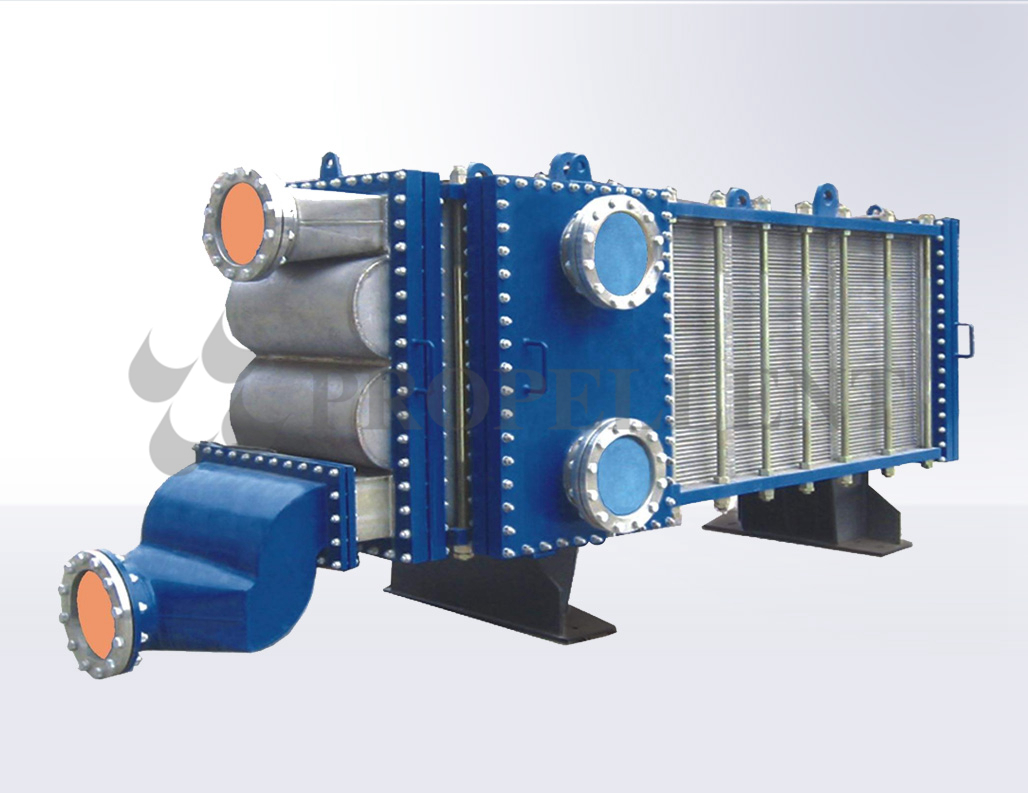

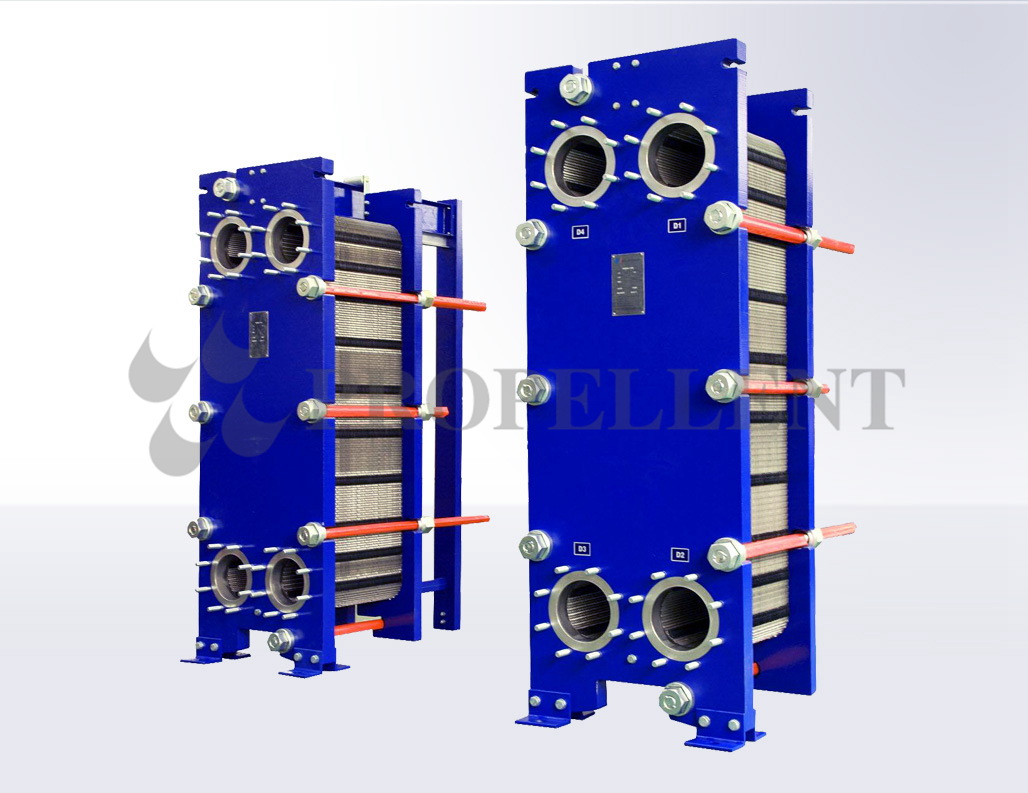

Plate heat exchanger is a new type of high efficient heat exchanger which is made of a series of corrugated metal plates. A thin rectangular channel is formed between the plates, and the plate heat exchanger is exchanged by plate. There are some problems in this process, and today we will discuss the precautions in the use of plate heat exchangers.

1. Precautions to prevent plate heat exchanger from freezing: When the temperature is below zero degrees centigrade, the water inside and outside the plate heat exchanger will freeze, and the volume will increase after freezing, resulting in the burst of plate heat exchanger. Therefore, the installation plate heat exchanger must be equipped with drainage equipment, so that the water is discharged when the plate heat exchanger is idle.

2. Dirt treatment in water: Solid dirt: a solid that does not melt in water, easily infarcted with a warm communicator ,The blunt object is not capable of being replaced by a cooler,The particle clutter should not be less than 0.8mm, and the initiative device is a 40-70 target filter, However, the work filter must protect the aged and remove the blunt object.

3. Corrosion resistance: Stainless steel has an anti-corrosive effect on a large number of chemicals, but is insensitive to chlorine anions. So we must restrict its light degrees in 280 PPM or more (less than 55 ℃). And the PH of the water must be somewhere.