Company news

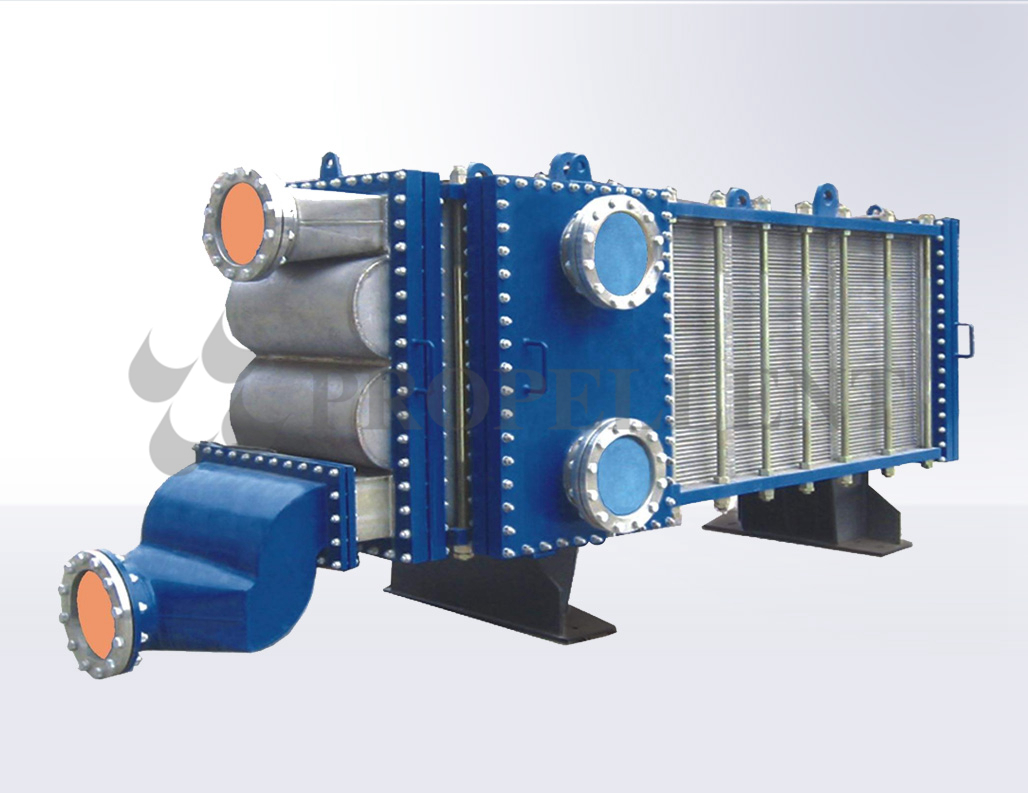

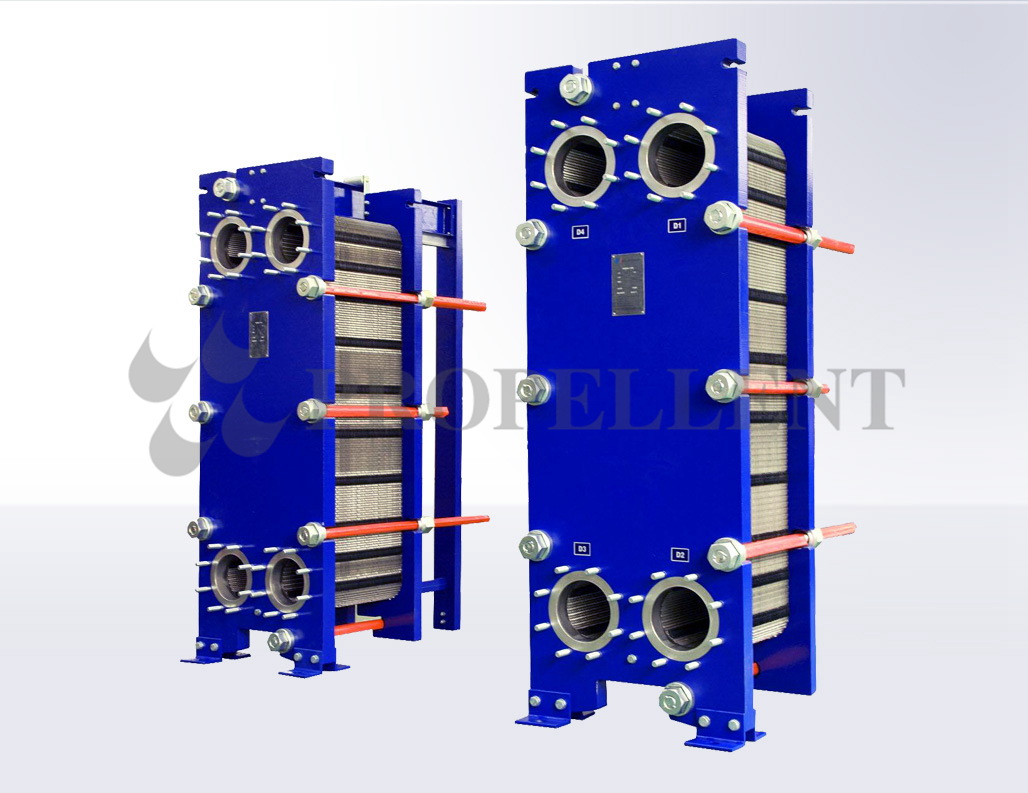

The design structure of plate heat exchanger

1. The plate heat exchanger is designed to ensure the homogeneity of the fluid distribution, and the design of sealing head, header, receiver and baffle is carried out.

2. To meet the heat and resistance performance of plate heat exchanger structure design, strength of key parts shall be check, in order to avoid limited the working status because of insufficient strength, lead to destruction or selection is too thick and cause waste;

3. The plate heat exchanger should consider maintenance (including cleaning, maintenance, maintenance, etc.) and transportation requirements.

4. The maximum working temperature and maximum working pressure of the plate heat exchanger, as well as the calculation results of thermal design and resistance, determine the material and dimension of each part to ensure its stable operation performance.

5. According to the working temperature, pressure and fluid properties of plate heat exchanger, the welding method and sealing material are selected.