Position: Home>News Center>News>What should I pay attention to when commissioning the "plate heat exchanger"?

News

What should I pay attention to when commissioning the "plate heat exchanger"?

Source

:http://www.puruipule.cn

Time:2020-06-23 10:56:23

Clicks:479

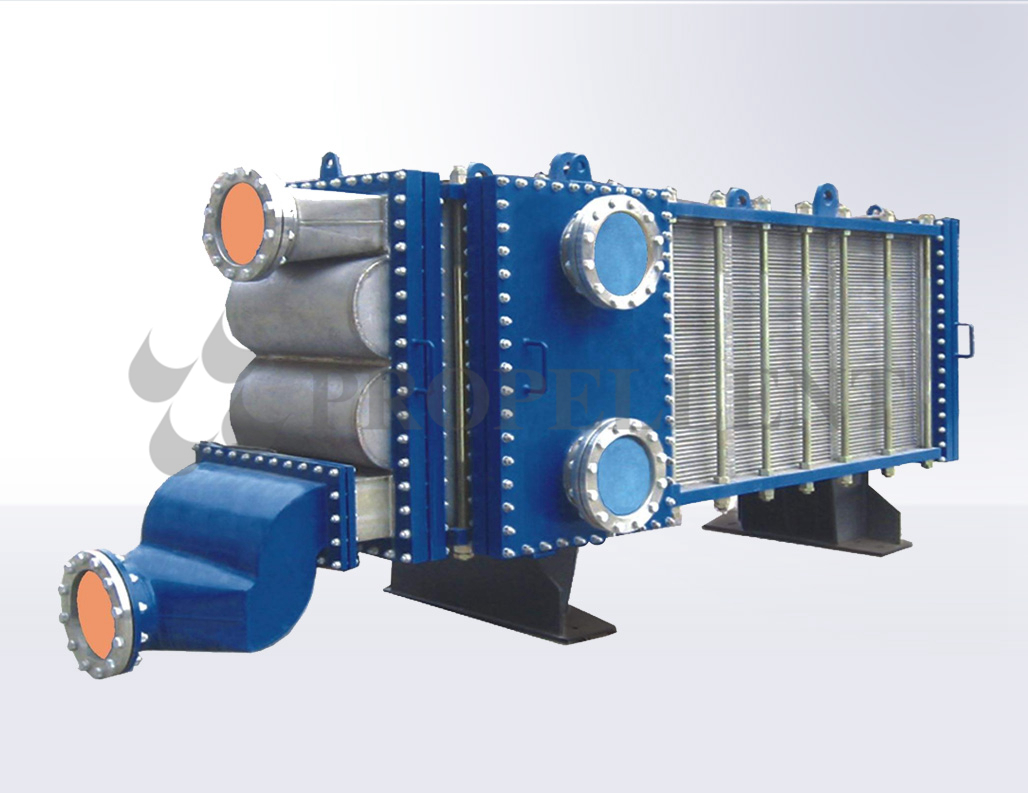

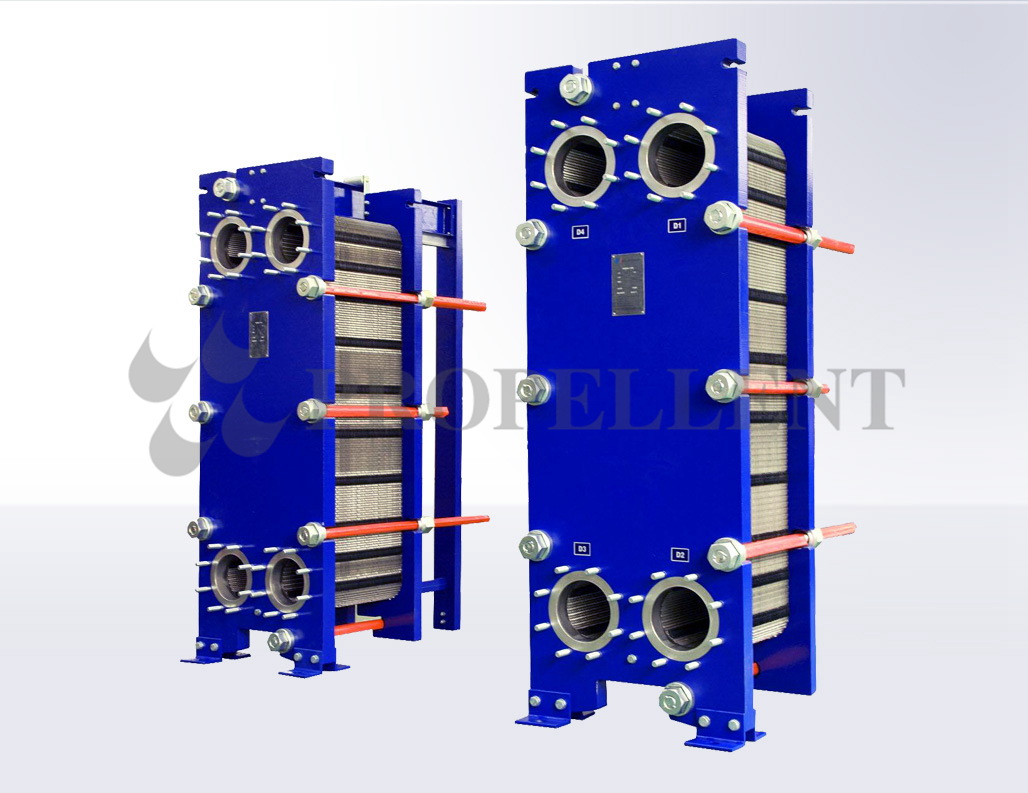

After the plate heat exchanger runs for a period of time, it will produce different degrees of dirt or deposits, increase the thermal resistance of the fluid, and reduce the heat transfer performance, so the heat exchanger should be cleaned regularly. After cleaning, in order to ensure the normal operation of the heat exchange equipment, it needs to be debugged before it is officially put into use. The following editors will introduce the precautions when debugging the plate heat exchanger:

1. Reserve a certain inspection site around the location where the plate heat exchanger is installed.

2. Clean the pipelines connected to it before installation to prevent sand, oil, welding slag and other debris from entering the plate heat exchanger, causing flow path obstruction or damage to the plate.

3. If the medium contains particulate matter or debris, install a filter or decontamination device at the inlet of the heat exchanger to avoid blockage of the heat exchange equipment.

4. Check whether the pipeline connection is correct, to avoid mixing the two media and cause adverse effects.

5. Check whether the clamping bolt is loose before putting it into use, and tighten it if any.

6. Start-up of plate heat exchanger

When starting, start the pump of the cold and hot medium, slowly open the inlet valve of the cold medium, and then open the inlet valve of the hot medium, so that the medium slowly flows into the heat exchanger to avoid excessive temperature.

1. Reserve a certain inspection site around the location where the plate heat exchanger is installed.

2. Clean the pipelines connected to it before installation to prevent sand, oil, welding slag and other debris from entering the plate heat exchanger, causing flow path obstruction or damage to the plate.

3. If the medium contains particulate matter or debris, install a filter or decontamination device at the inlet of the heat exchanger to avoid blockage of the heat exchange equipment.

4. Check whether the pipeline connection is correct, to avoid mixing the two media and cause adverse effects.

5. Check whether the clamping bolt is loose before putting it into use, and tighten it if any.

6. Start-up of plate heat exchanger

When starting, start the pump of the cold and hot medium, slowly open the inlet valve of the cold medium, and then open the inlet valve of the hot medium, so that the medium slowly flows into the heat exchanger to avoid excessive temperature.

Keywords:plate heat exchanger