News

Precautions for plate heat exchanger during commissioning

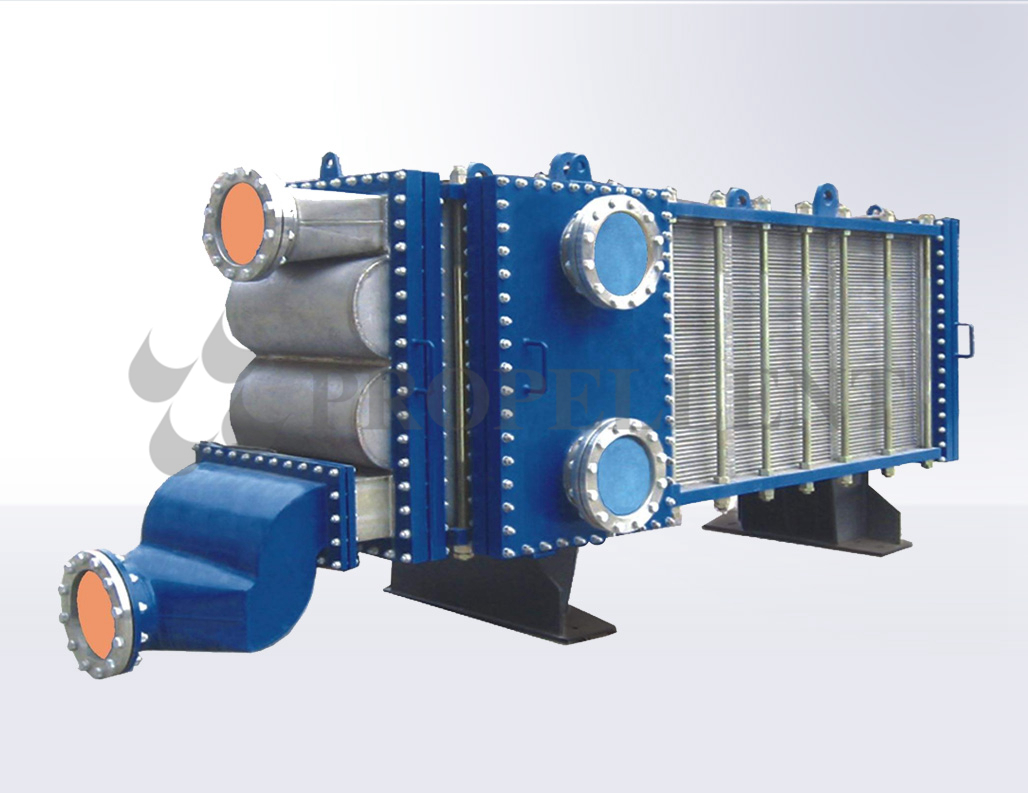

Because the plate heat exchanger works for

a long time, the surface of the heat transfer plate will produce different

degrees of dirt or deposits, thereby increasing the flow resistance and

reducing the heat transfer performance. These are mainly the pressure

difference between the inlet and outlet pressure gauges and the temperature of

the cold medium outlet. Reduced, so we have to clean it, we need to debug the

experiment after the cleaning is completed to ensure the normal use of the

product, then what are the things we need to pay attention to during the

debugging process?

1.

A certain inspection site should be reserved around the location of the plate

heat exchanger.

2.

Before installation, the pipeline connected to it should be cleaned to prevent

sand, oil, welding slag and other debris from entering the plate heat

exchanger, causing obstruction of the flow channel or damage to the plate. The

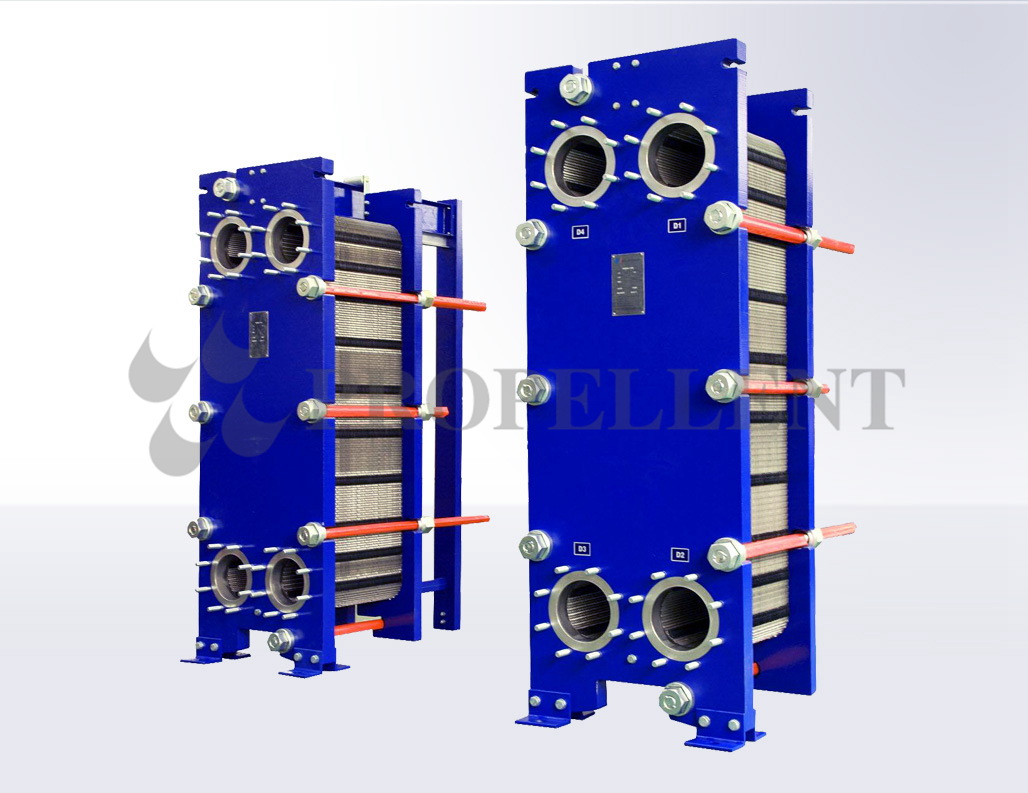

plate heat exchanger has a small footprint and light weight. Except for the

volume of the device itself, no additional inspection and installation space is

required, and the thickness of the plate used for heat exchange is 0.6-0.8 mm.

3.

Opening and stopping sequence of plate heat exchanger

When

shutting down, first close the high-pressure side medium solenoid valve, and

then close the low-pressure side medium solenoid valve. In today's exaggeration

of high efficiency, environmental protection and energy saving, the advantages

of plate heat exchangers in the field of heat exchange have become increasingly

prominent, and can be used in heating, cooling and food disinfection in various

processes, in terms of low-grade heat energy recovery. It also has significant

economic benefits.

When

starting up, first open the low-pressure side medium plunger valve, and then

open the high-pressure side medium plunger valve slowly after the medium fills

the plate heat exchanger channel.

4.

Check if the clamping bolts are loose before putting into use. If necessary,

tighten them. In recent years, plate heat exchangers have replaced traditional

shell-and-tube heat exchangers in airports, hotels, commercial buildings, etc.,

and have achieved good results.

maintenance:

5.

If there are often large particles of muddy sand or debris in the medium, the

supporting decontamination equipment produced by our factory should be arranged

in front of the plate heat exchanger. The plate heat exchanger has a low

fouling coefficient, and the fluid violently rolls between the plates to form a

turbulent flow. The plate design avoids the existence of a dead zone, so that

impurities are not easily deposited and blocked in the channel, and a good heat

exchange effect is ensured.

The

above is the various things we need to pay attention to during the debugging

process after cleaning. When we understand these matters, we can guarantee the

better use of the product.