Industry news

Oil gas petrochemical industry plate heat exchagers

In the petrochemical industry, there are many types of heat exchangers, and they have extremely high requirements for pressure and temperature. The high-efficiency application of heat exchangers can increase the energy efficiency of the petrochemical industry, prevent unnecessary production stoppages, and avoid product damage caused by problems in the heat exchanger.

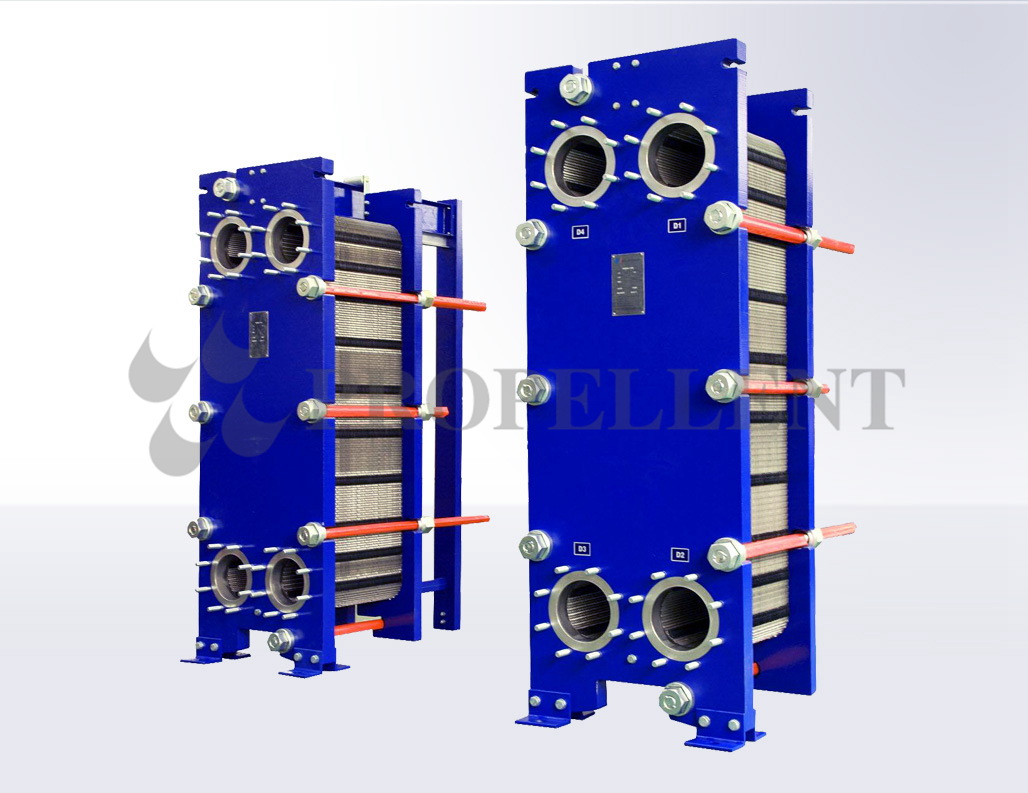

High-efficiency plate heat exchanger: better able to cope with higher pressure and higher temperature. Specifically, welded plate heat exchanger has strong convenience, small size, light weight and good heat transfer. Performance and low price, therefore, have been better applied in the production of petroleum. High-efficiency plate heat exchangers are capable of cooling mechanical lubricants and fresh water, cooling associated intermediates in oil fields, and can also be used to heat crude oil.

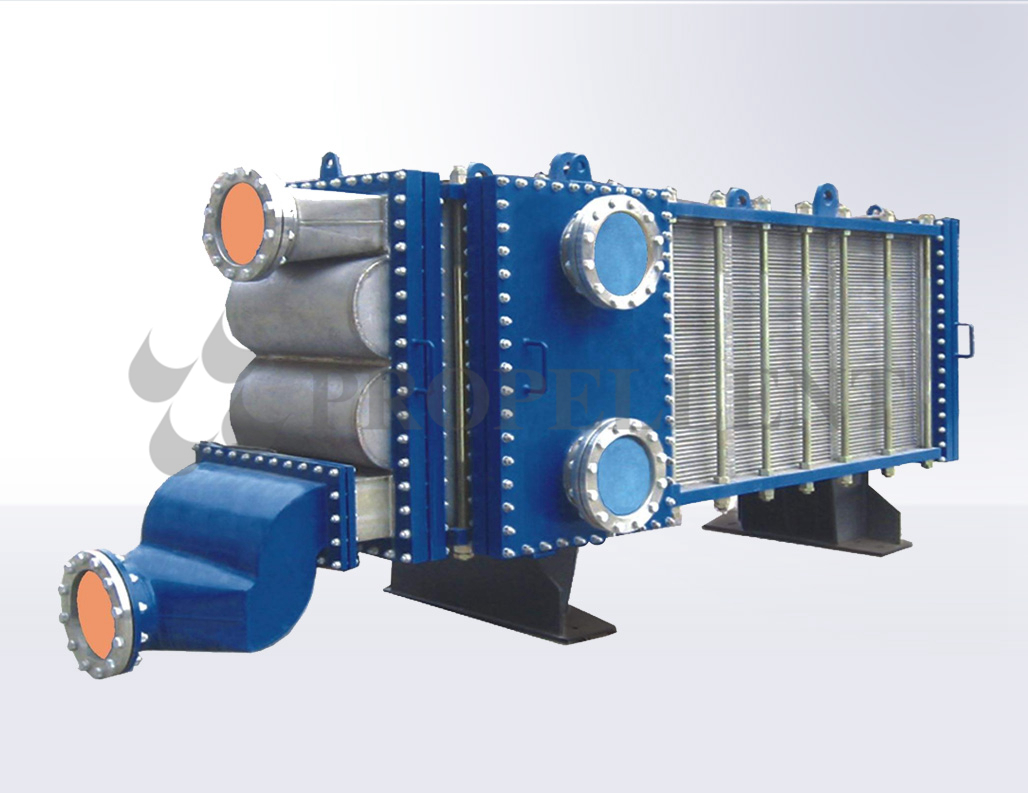

Spiral baffle heat exchanger: This is a modern high-efficiency heat exchanger facility. It is widely used in the petrochemical industry in many countries and regions around the world, including: high heat transfer coefficient and self-energy Scouring anti-deposition and so on, so the spiral baffle heat exchanger has achieved very good application in the petrochemical industry, it can heat and cool alcohol, resin, urea, small molecule polymerized olefins, gasoline and diesel , ammonia, etc., its application value is very specific.