Industry news

Under these conditions, please use plate heat exchanger carefully!

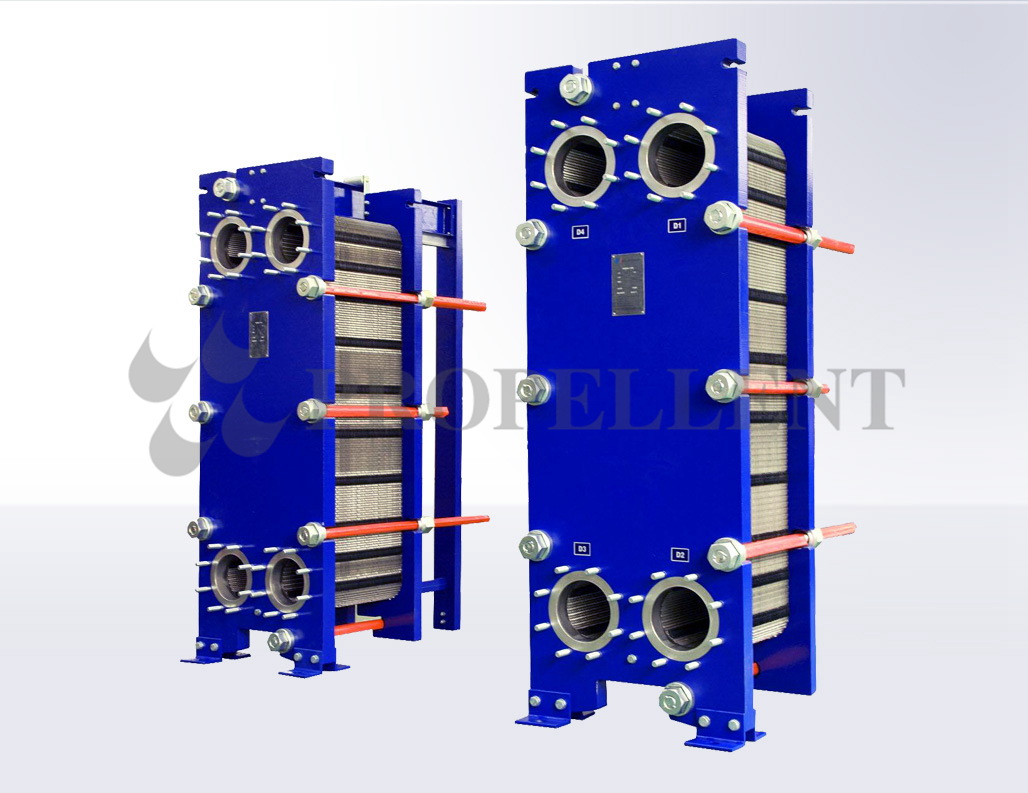

1. Plate heat exchanger is an ideal heat exchange equipment for liquid-liquid exchange, generally does not apply to the heat of the gas, if to be applied to the working condition of the gas, also have the gas phase changes in working condition;

2. If the medium for heat exchange is explosive and flammable, the design pressure of the selected plate heat exchanger should be at least one nominal level higher than that of the medium for heat exchange. The corresponding sealing gasket must also be high temperature resistant, corrosion resistant and reliable;

3. If the heat exchange medium is highly corrosive, a protective cover should be set around the plate group when designing the plate heat exchanger.

4. When there are more impurities in the medium involved in heat exchange, it is better to set up the filter at the inlet pipe of the plate heat exchanger and arrange it one way. In addition, the plate with a large gap in the channel should be selected.

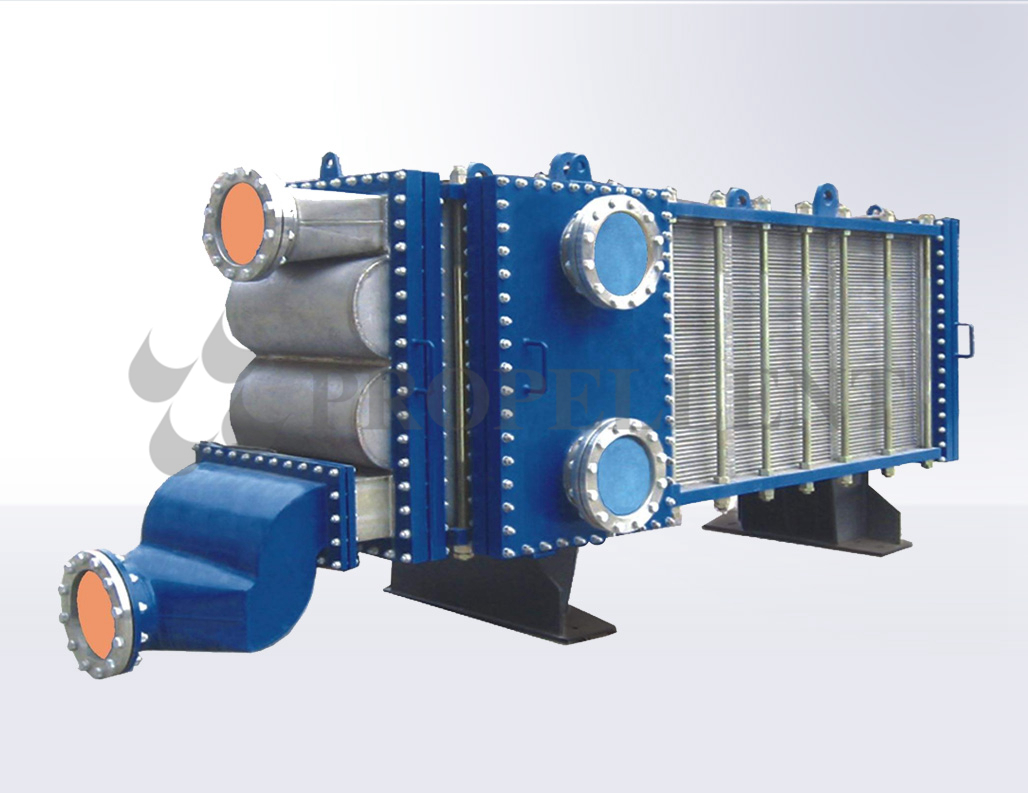

5. When the working condition is high temperature and high pressure, the detachable plate heat exchanger cannot adapt to it. The all-welded plate heat exchanger, semi-welded plate heat exchanger or plate and frame plate heat exchanger can be selected.