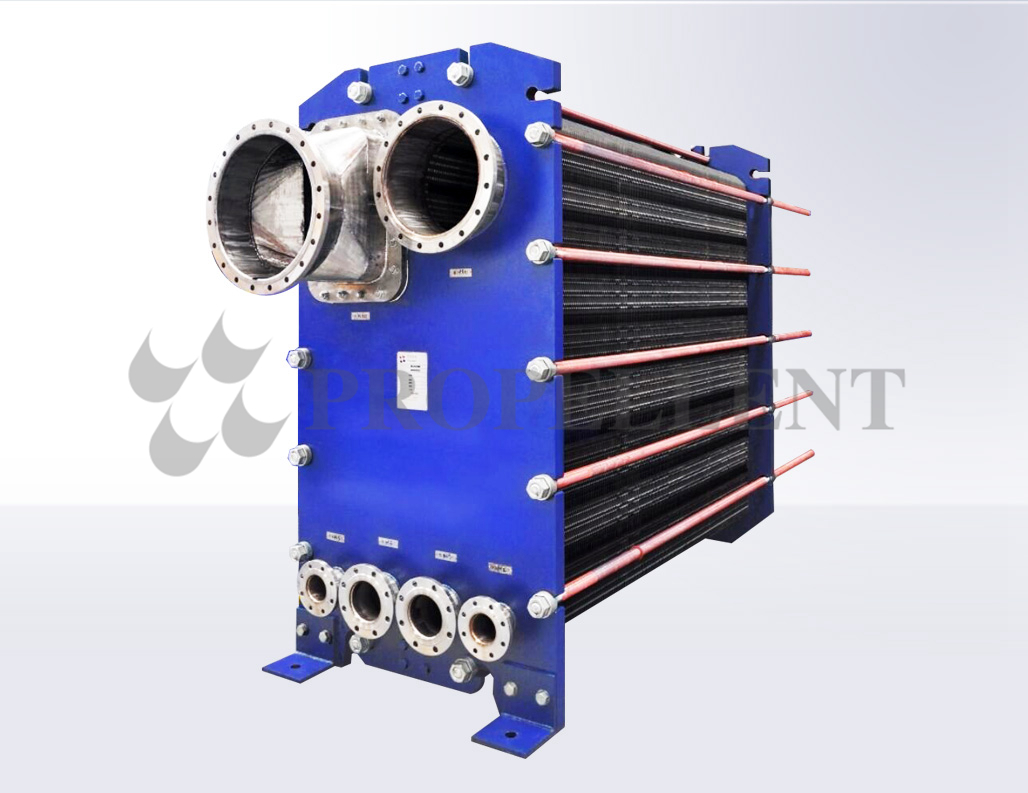

Plate evaporators and condensers use climbing-falling film evaporation, the materials pass between the plates and are heated by steam to evaporate, Liquid-vapor mixture is discharged at the exit and then enters the separator, it is separated in the separator to obtain concentrated materials and secondary steam. Enrichment of the material and the second steam will continue to evaporate into the next level of evaporator, It has high thermal efficiency, compact structure, convenient disassembly cleaning.

The plates of evaporator and condenser is a kind of multistage evaporation, which are special for condensing temperature and vacuum and multistage evaporator, the unique asymmetric large port design ensures the best function of heat exchange area. Unique entrance design and efficient thermal efficiency makes the plate component has become today's most efficient market plate component.

The features of plate evaporator:

1) It is high heat transfer efficiency, heat transfer coefficient is big, strong evaporation. The design of plate corrugation is aimed at high coefficient of thermal conductivity of thin film, Fluid has a powerful disturbance flow at the low speed, Generally speaking, Heat transfer coefficient K value of plate heat exchanger is in the range of 3000-6000 - w/m. ℃.

2)Evaporation speed is quick and evaporation temperature is low. Products stay shortly at the period of evaporation process, it is a short time from material to product, it is applies to specially high protein content, heat-sensitive material enrichment because the quality is not destroyed.

3) Small occupation, compact structure and low height of equipment, it is convenient to operate because the valve position of the pipe is low, the device itself can provide maintenance space, do not need other dismantling space and small space can be composed of large heat transfer area.

4) It is easy to install, short installation time and low cost.

5)Small heat loss because of compact structure and small volume, the external surface area is also small, the equipment do not need heat preservation in general.

6)It is beneficial to the use of a cold reservoir, it is safe to use and has a flexible combination.

7) Flexible operation, convenient cleaning, Plate evaporator, plate condenser and plate heat exchanger, compact structure, convenient dismantling and easy cleaning. It can adjust the processing capacity of the entire equipment and the size of the process quantity.

8)On the premise of low cost with same rate of heat transfer, the investment cost will be greatly reduced because the value is reduced, such as low metal consumption, occupied area, fluid resistance etc.

Our selection methods:

We will look for insights into your technology and have an effective communication with your engineer to settle down a perfect solution, this solution will be more accurate and apply to users’ working condition, it will be in favor of reducing purchase cost and energy consumption (water, electricity and gas)

Our technical engineer can provide professional selection solution and drawings for our clients by calculation software according to users’ working condition, we will select fitting solution to give you stable and efficient service.

We will be more responsible for your working conditions to reduce your equipment procurement costs and energy consumption of your process operation(water, electricity, gas).

- Last: Wide-runner pla

- Next: Finned Tube Hea